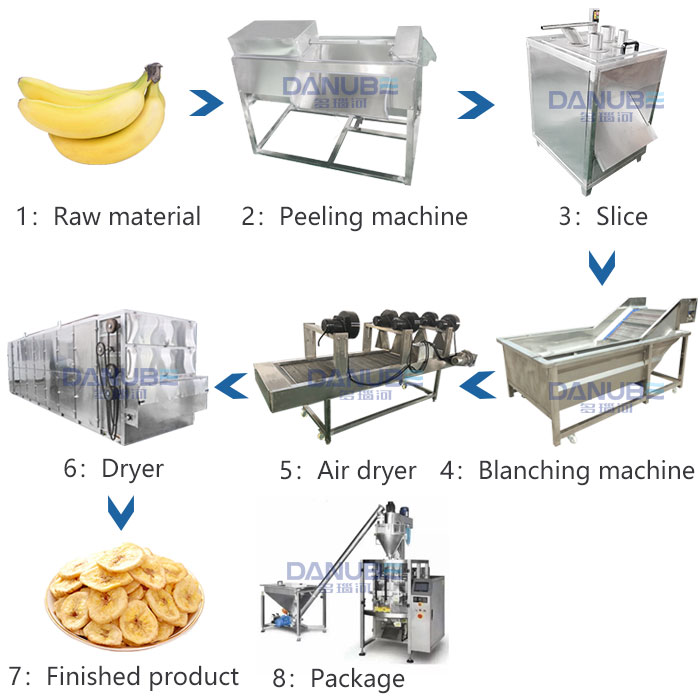

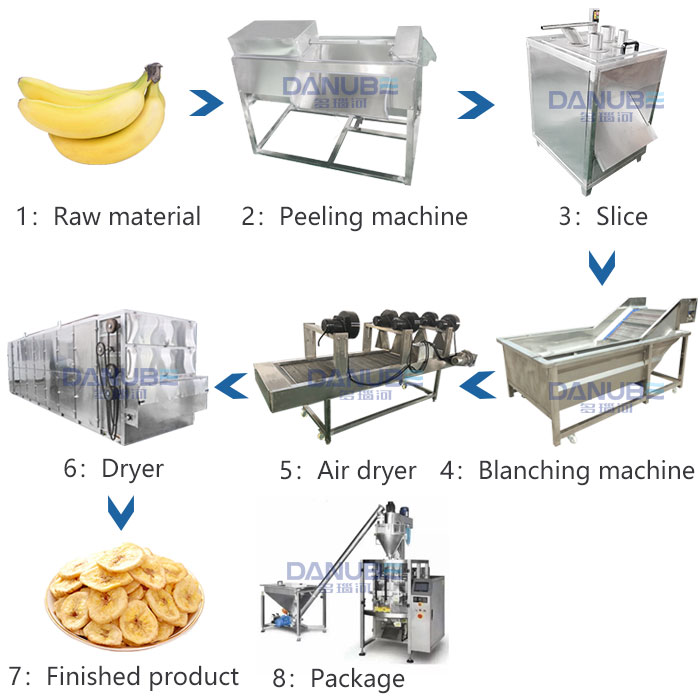

Production introduction

The banana drying line has the characteristics of continuous automated production, fast processing speed, high output, and good quality. The low-temperature drying method maintains the original flavor of the banana.

It includes banana peeling machine, banana slicer, banana blanching machine, banana dryer, banana packaging machine and other equipment processing lines, and can also be used for other fruits such as mango, grapes, tomatoes, etc.

In addition, bananas are easier to store, avoiding economic losses caused by seasonal storage and mildew. The banana dryer processing line adopts advanced technology, has a high banana output, and is sold directly at the factory price. This is the best choice for the banana industry and is currently the most ideal equipment for banana processing

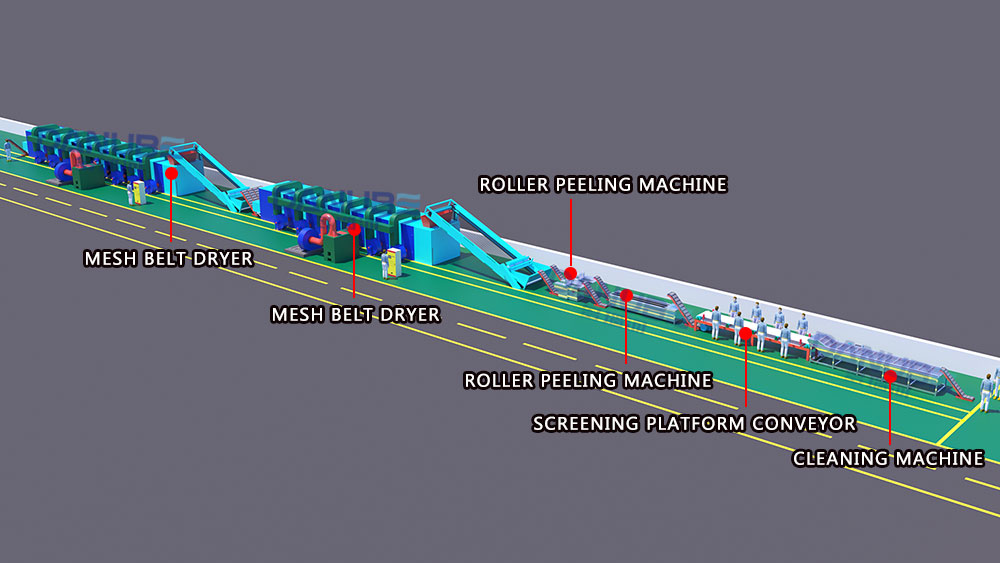

Product components

A complete banana processing plant mainly includes banana peeling machine, banana slicer, banana blanching and soaking machine, banana dryer, banana chip grinding machine, banana powder packaging machine, and other equipment.

Banana peeler:The first step in a banana processing line is to peel the bananas. The banana peeling machine adopts manual feeding and automatic peeling process, which can quickly remove the banana peel, and the peeling is clean and not damaged. Perfectly peels bananas of any camber, any size, any shape. The peeling effect is good and the speed is fast. It is the latest technology product exclusively invented in the world, and it is also a must-selected product for the global banana processing plants.

Banana slicer: The banana slicer is used to cut bananas into thin slices of uniform thickness, and the thickness of the slices can be adjusted as needed. The slicer has a good effect, the banana cutting surface is smooth and even, not broken. Made of food-grade stainless steel, healthy and safe. Simple operation, high efficiency, and easy cleaning.

Banana blanching and soaking machine: reduce the outflow of banana juice, prevent the oxidation of bananas, protect the color of bananas, and soak the bananas at the same time, so that the produced bananas are tastier. The water temperature of the machine is controllable, and the material used is stainless steel, which is safe and hygienic, and easy to clean. The water can be circulated, the conveying speed can be adjusted, and the operation is simple.

Multi-layer belt banana dryer:The dryer is the key equipment, which determines the effect and quality of the banana after processing. Using our mesh belt type banana dryer, with an intelligent control system, can make banana the drying is always maintained in a reasonable drying environment to ensure the effect of the finished product. This banana dryer has the advantages of large processing output, high degree of automation, controllable drying effect and quality, and adjustable drying time. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Banana powder making machine:Grind the dried banana chip to a fineness of 10-120 mesh, and obtain the particle size of banana powder by selecting screens with different apertures. the banana grinder has simple structure, stable operation, low noise, and good crushing effect. Air-cooled or water-cooled, Prevents damage to the ingredients of banana powder during milling.it can work continuously for a long time.

Banana powder packing machine:The banana powder packaging machine adopts PLC control system, which is intelligent and controllable, and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted. It can automatically complete the tasks of banana powder measurement and filling, with high precision, small error, intelligent bag delivery, adjustment of bag width, and filling of banana powder. It is suitable for all kinds of fine powders with good fluidity.

Advantages of the banana processing line:

1: Customizable.

Different production lines are configured according to customer production requirements.

Banana production lines are available in two types: fully automatic and semi-automatic. Customers can choose according to their own needs.

2: Easy to operate.

The banana production line is easy to install and can be used after connecting to the power supply. It is reliable to use and easy to disassemble.

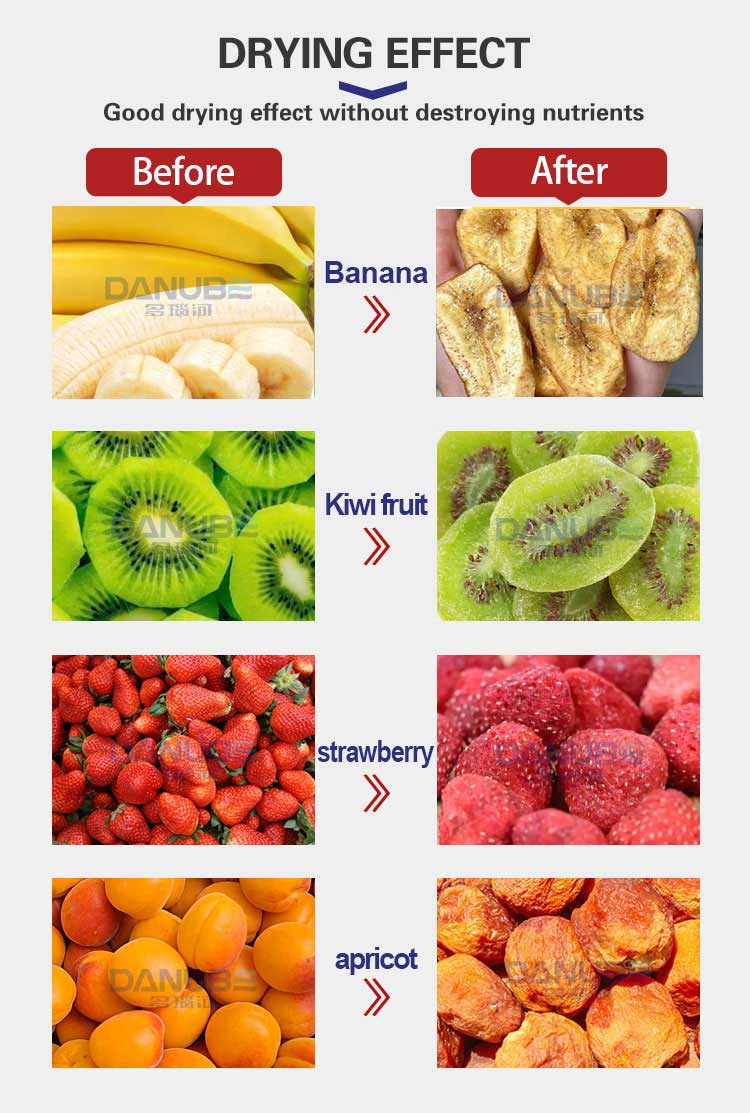

3: High quality bananas.

The dryer uses medium and low temperature drying. After drying, the original color and nutrients of the bananas can be completely retained. The equipment is made of stainless steel and meets food machinery standards.

4: The heat source of the dryer is flexible: coal, sawdust, natural gas, diesel, propane, electricity, etc.

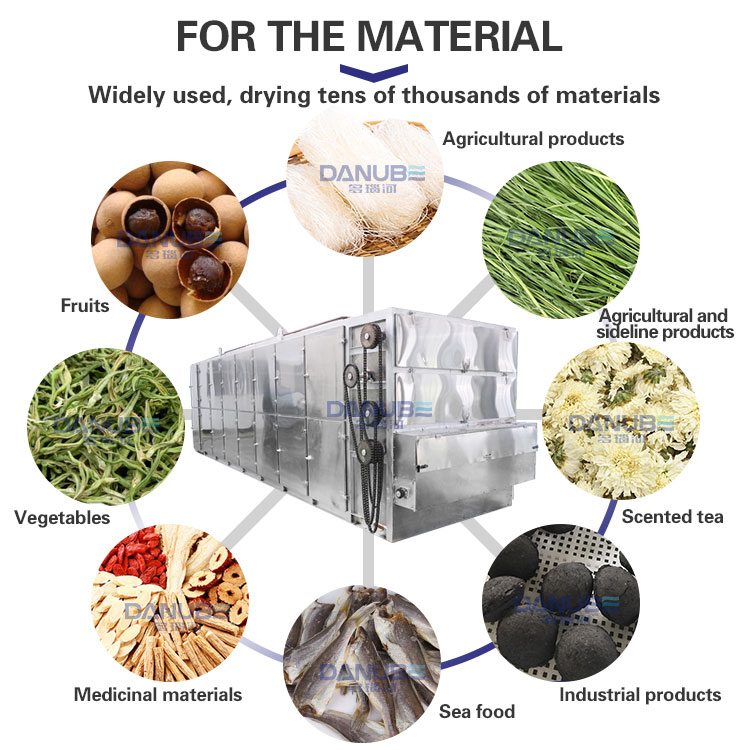

5: Wide range of applications:

Most of the machines in the production line are not only suitable for bananas, but also for other fruits and vegetables.

| Banana Chips Production Line | |||

| No. | Machine Name | Powder | Size |

| 1 | Banana Slicing Machine | 1.5KW | 1100x800x1500mm |

| 2 | Elevating Conveyor | 0.55kw | 2000x800x1300mm |

| 3 | Sugar Soaking Machine | 120kW | 4500x1200x1300mm |

| 4 | Air Drying Machine | 7.1kw | 4000x1000x1500mm |

| 5 | Continuous Frying Machine | 120kw | 4000x1100x2200mm |

| 6 | Vibration Deoiling Machine | 0.5kw | 1800*1000*1300mm |

| 7 | Pre-cooling Machine | 7.1kw | 4000x1000x1500mm |

| 8 | Elevating Conveyor | 0.55kw | 2000x800x1300mm |

| 9 | Seasoning Machine | 1.5kw | 3000*1000*1600mm |

| 10 | Weighing Packaging Machine | 6kw | 3500*2700*3600mm |

| Support customization according to customer requirements. | |||