【Video display – click to play】

Introduction of electric wire Shredder

electric wire shredder machine has been designed for a wide array of applications and industries, suitable for shredding solid material such as electric wire, cable, Steel Wire, wood crates, Used car shells, metal, Industrial waste,Waste furniture,tire,plastic bucket,bone,waste paper,Gasoline tank,Solid Waste. etc.

Structure of electric wire Shredder

electric wire shredder equipment is composed of frame, cutter head, blade part, power system, conveying system, and other parts. The tree technology shredding frame is welded with a high-strength steel plate, which is the supporting foundation of the whole equipment.

The electric wire shredder enters the inside of the shredding box through the feeding system. The shredding blade is carried on the board of the electric wire shredder. The pushing box pushes the material to the vicinity of the blade, and the material is torn, squeezed, and sheared It can be shredded into small pieces and discharged from the screen holes, which is very suitable for the crushing treatment of all kinds of waste and miscellaneous electric wire and other materials.

Heavy-duty electric wire shredder equipment can quickly shred waste and electric wire into 3~5cm, and the size can be determined according to user needs. When discharging

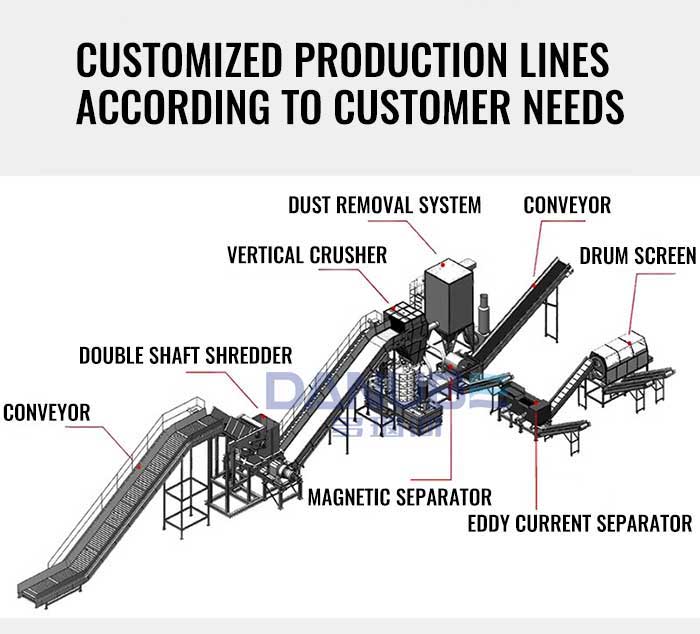

electric wire shredder equipment can complete electric wire shredding and metal separation at one time so that the recycled electric wire can be used well.the equipment is novel in design, easy to operate, low energy consumption, high output, and low noise.

electric wire Shredder Machine Technical Features:

1. Our shredders can be employed as either a primary or secondary shredder and can be seen working anywhere from the waste management company to biofuel producers;

2. Dual shafted, slow-speed, high-torque waste shredder with hardened steel cutters;

3. The two cutting rotors powerfully grab the feed material, and no matter the feed material is a large piece of hard plastic or heavy tires, this machine can easily shred them into small pieces;

4. Double shaft shredder is able to process a number of different materials; shredder is designed with a powerful engine, long working length and aggressive input, Internal feeding volume bigger than traditional and common single shaft shredder machine and allow you using a forklift truck to feed.

5. Heavy structure: the frame and structure of our shredders are made of high-thickness sheets and tubular. Blades are manufactured from high-quality steel, suitable for shredding tough materials and for extra long life;

6. Depending on the requirement, these discs (blades) are available in a wide range of quantities, qualities and shapes with the new double-shaft shredder;

7. Any overloads caused by foreign material are sensed by the PLC controller and cause the shaft rotation to stop and reverse direction to clear the foreign matter, and then resume;

8. Cutters removal and replacement can be carried out safely and simply.

9. Our shredders Use a planetary reducer, not a traditional gearbox.

Taiwan Customer Case

Indian customer site