【Video display – click to play】

Industrial Waste Shredding Production Line

The line is a kind of equipment system specially used for processing industrial waste, which can efficiently crush, sort and recycle various types of waste industrial materials. Industrial waste includes but is not limited to waste equipment, waste plastics, waste metals, waste paper, waste cloth, wood, rubber, electronic waste (such as waste electrical appliances, electronic components), etc. Through shredding and sorting, these wastes are converted into recyclable resources or raw materials for further processing to reduce environmental pollution, reduce garbage accumulation, and promote resource reuse.

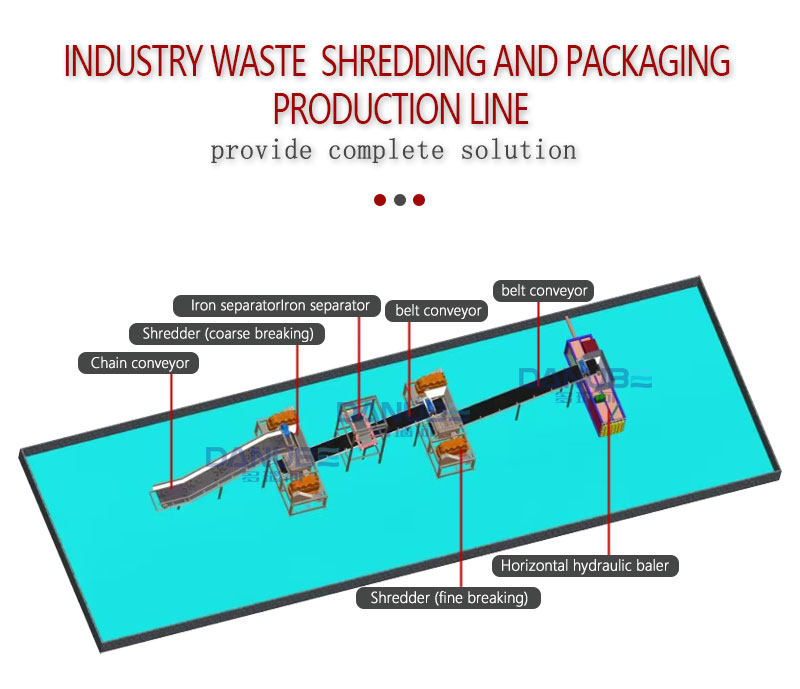

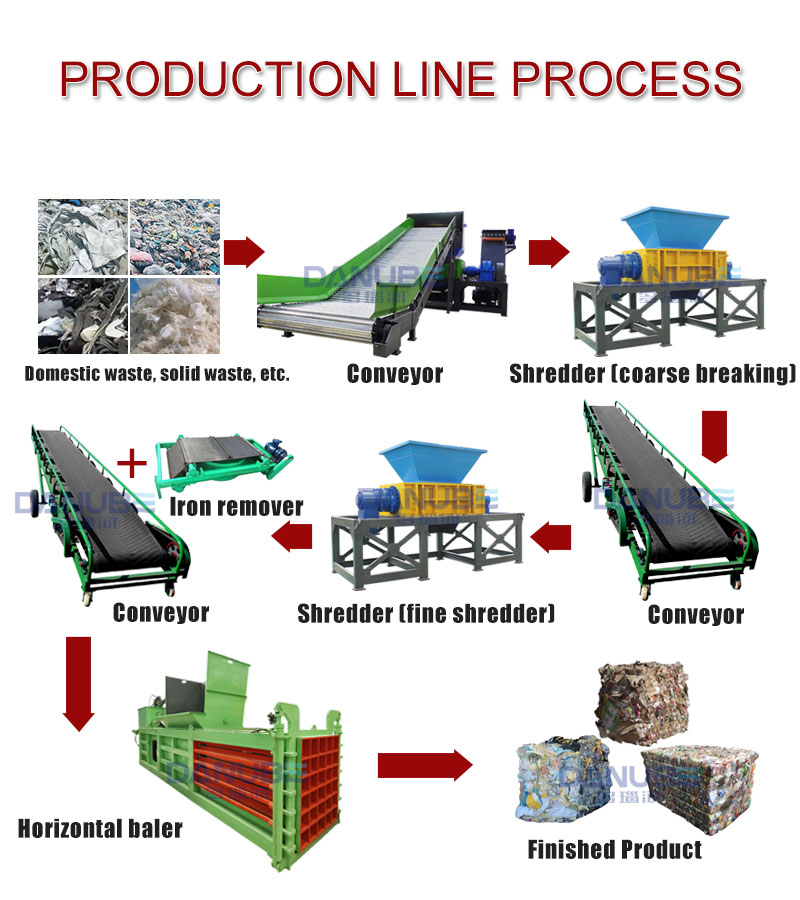

Components of Industrial Waste Shredding Production Line:

1. Shredder: It is the core equipment of the production line, mainly responsible for crushing industrial waste. Common types of shredders are:

– Double-axis shredder: It is suitable for processing larger and harder waste by tearing with two counter-rotating blades.

2. Conveying system: Use conveyor belts, vibrating feeders or screw conveyors to evenly transport waste to each processing unit to ensure the smooth operation of the production line.

3. Screening equipment: used to separate the crushed materials, usually using equipment such as vibrating screens and drum screens to sort the materials according to their size.

4. Magnetic separator: used to recover the metal components in the waste, using magnetic force to separate ferromagnetic materials from other materials, commonly used in recycling scrap steel or other metals.

5. Airflow sorting system: separates materials of different densities and weights through airflow, and separates light materials (such as plastics, paper, etc.) from heavy materials (such as metals, glass, etc.).

6. Automatic control system: modern industrial waste shredding production lines are usually equipped with advanced PLC control systems to automatically control the operation of the entire production line, improve operational efficiency and production safety.

7. Baler: used to pack the recycled materials for easy storage and transportation. The packaged materials can be further sent to recycling plants or end users.

Application areas:

1. Scrap metal recycling: Scrap metals (such as scrap steel, scrap aluminum alloys, scrap copper, etc.) generated during industrial production can be recycled and reused to make new metal products after being crushed and sorted through the shredding production line.

2. Waste plastic recycling: Plastics and waste plastic products discarded during the production process can be recycled and regenerated by shredding and sorting to make new plastic products.

3. Electronic waste treatment: Disposal of discarded electronic equipment (such as mobile phones, televisions, computers, etc.) to recover valuable raw materials such as metals, plastics and batteries.

4. Waste equipment treatment: Recycling and resource treatment of waste mechanical equipment, auto parts, home appliances and other waste.

5. Construction waste treatment: Treatment of waste generated during building demolition, such as scrap steel, wood, concrete, etc., by shredding and recycling to reduce the pollution of construction waste to the environment.

6. Rubber waste recycling: Recycling of waste rubber products (such as waste tires) for reprocessing and reuse.

The industrial waste shredding production line is an advanced waste treatment system that converts industrial waste into recyclable resources or other usable raw materials through multiple links such as crushing, screening and sorting. It not only helps to improve the recycling rate of resources and reduce the pollution of waste to the environment, but also reduces the production cost of enterprises and promotes green and sustainable development.

Malaysia customer site

Korea customer site