【Video display – click to play】

Large Waste Shredding Production Line

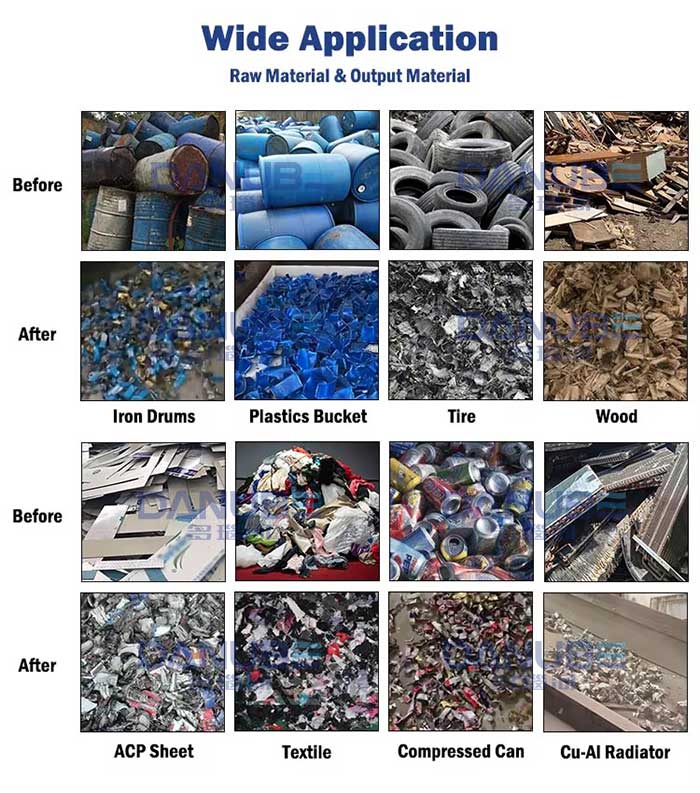

The line is a kind of equipment system specially designed for processing large garbage, waste and waste items. The production line can effectively dismantle and crush large discarded items (such as furniture, household appliances, construction waste, auto parts, waste wood, metal, etc.) for subsequent classification, recycling and treatment. Its main purpose is to realize the resource utilization of waste, improve the efficiency of waste treatment and reduce the volume of waste.

Working principle:

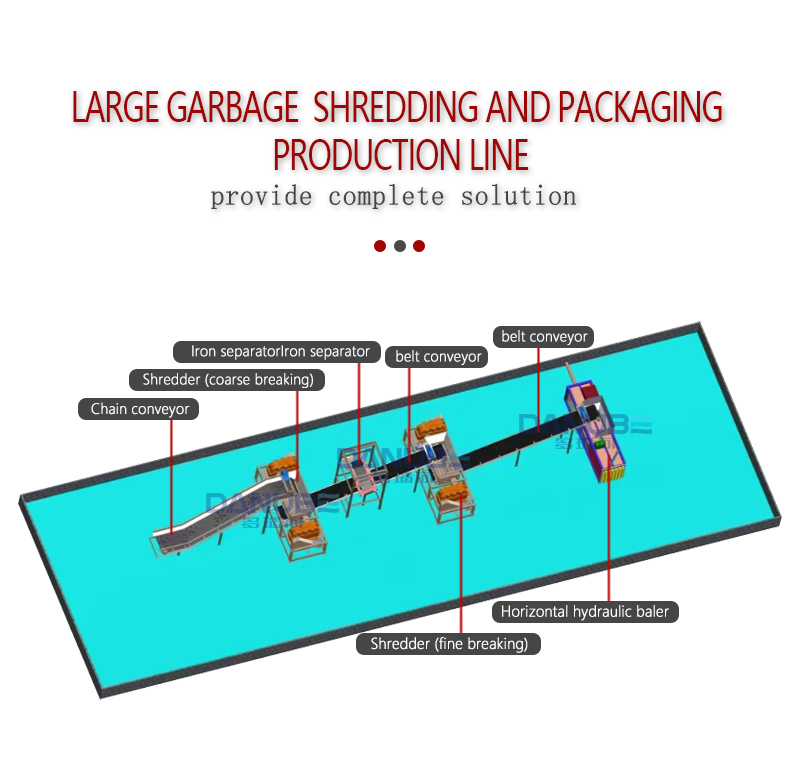

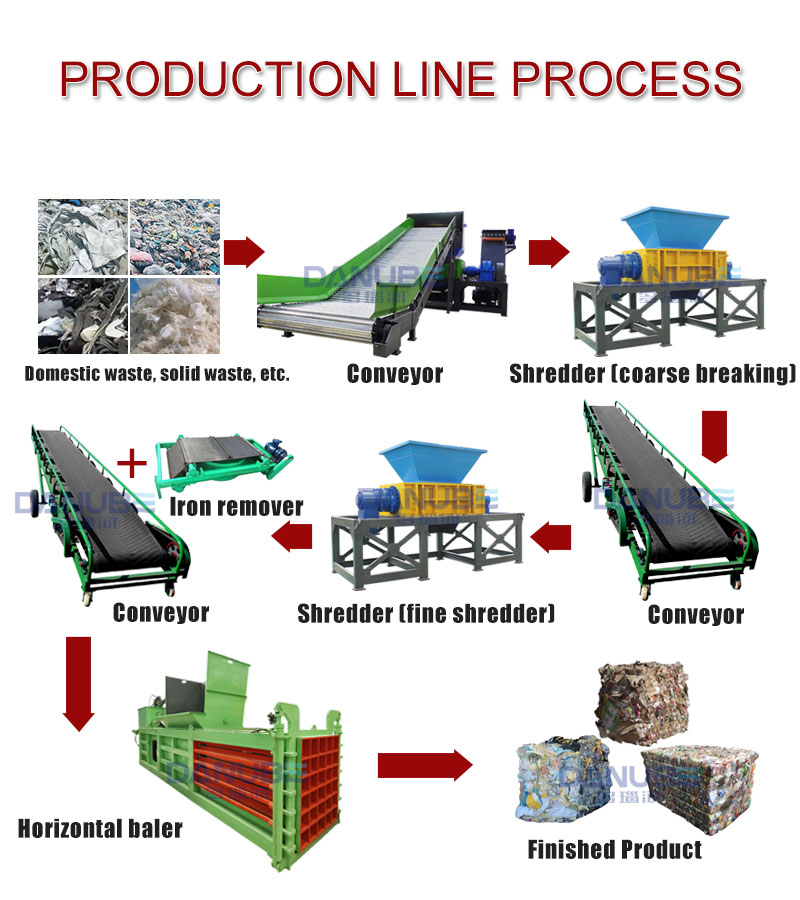

1. Feeding system: After pre-treatment (such as sorting, screening, etc.), large garbage is fed into the feed port of the shredder through a conveyor belt or manual method.

2. Shredding stage: The shredder uses a powerful blade system (single-axis, double-axis or multi-axis design) to tear large garbage and break it into smaller pieces. Shredders usually use hydraulic systems or mechanical drives to provide high-strength tearing capabilities.

3. Screening system: The crushed garbage fragments are sorted through the screening device to remove fine substances or unnecessary debris so that the appropriate materials can be processed later.

4. Sorting and recycling: The shredded materials are separated into recyclable metals, plastics, wood, paper and other raw materials through magnetic separation, air flow separation, manual sorting and other equipment for further recycling.

5. Output system: The processed recyclable materials, waste or finished products are usually output through conveyor belts and sent to the next link or storage, while the discarded parts may be sent to landfills or used for energy recovery.

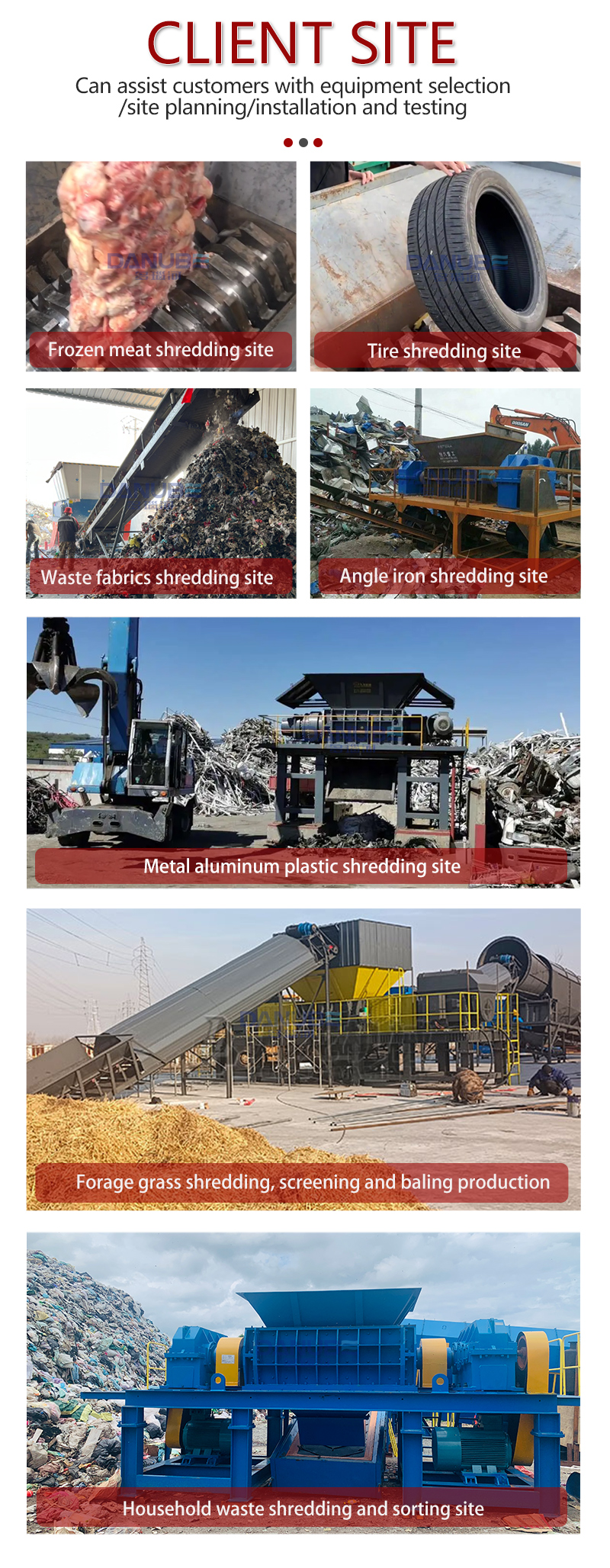

Application areas of large-scale garbage shredding production line:

1. Waste recycling and treatment: Through shredding and sorting, reusable materials such as metals, plastics, and wood are recovered from waste furniture, home appliances, automobiles, construction waste and other items.

2. Waste incineration and energy recovery: After processing large discarded items, the remaining organic matter or other combustible substances can be used for waste incineration power generation or energy recovery.

3. Environmental protection: Reduce the accumulation and landfill of large garbage, and reduce environmental pollution through crushing and recycling.

4. Industrial waste treatment: Suitable for processing large waste generated in the production process of enterprises, such as waste equipment, scrap steel, etc.

5. Construction waste treatment: Crushing and recycling waste in construction projects, especially valuable recycled materials such as wood, steel, and plastic.

Advantages of large garbage shredding production line:

1. Efficient processing of large garbage: It can quickly process large and heavy waste and improve garbage processing efficiency.

2. High resource recovery rate: Through the sorting system, recyclable metals, plastics, wood, etc. can be effectively separated to improve resource utilization.

3. Reduce environmental burden: After large garbage is processed, it can effectively reduce the pressure on landfills and reduce environmental pollution.

4. Reduce transportation and storage costs: Through crushing, the volume of garbage is reduced, which is convenient for transportation and storage.

5. High degree of automation: Modern production lines are equipped with advanced automatic control systems to reduce manual intervention and improve production efficiency.

The large garbage shredding production line is an efficient waste treatment equipment that can crush and recycle large discarded items, reduce the volume of garbage, recover valuable resources, and provide a basis for subsequent treatment of waste (such as incineration power generation, landfill or secondary recycling). By realizing waste resource utilization, it not only helps environmental protection, but also helps reduce operating costs and improve resource utilization efficiency.