【Video display – click to play】

Plastic shredder recycling processing production line equipment is mainly used to shred high-density polyethylene HDPE plastic products and materials, which is conducive to plastic recycling and regenerated plastic particles. For example mineral water bottles, PET bottles, oil bottles, gasoline bottles, plastic bottles, plastic bags, plastic sheets, plastic boxes, etc.

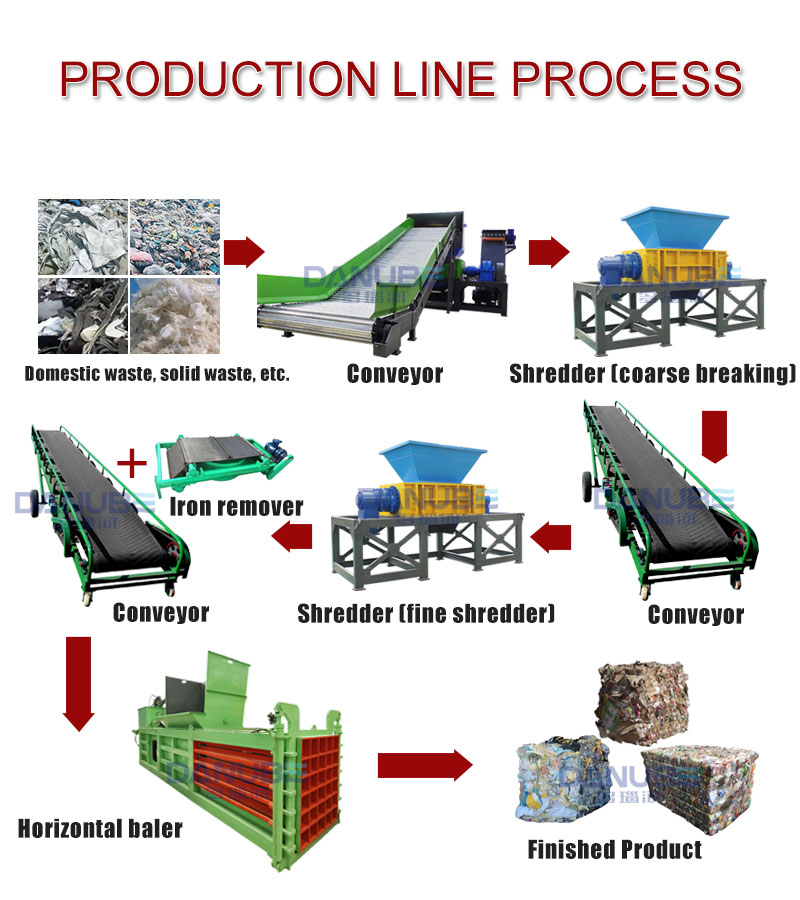

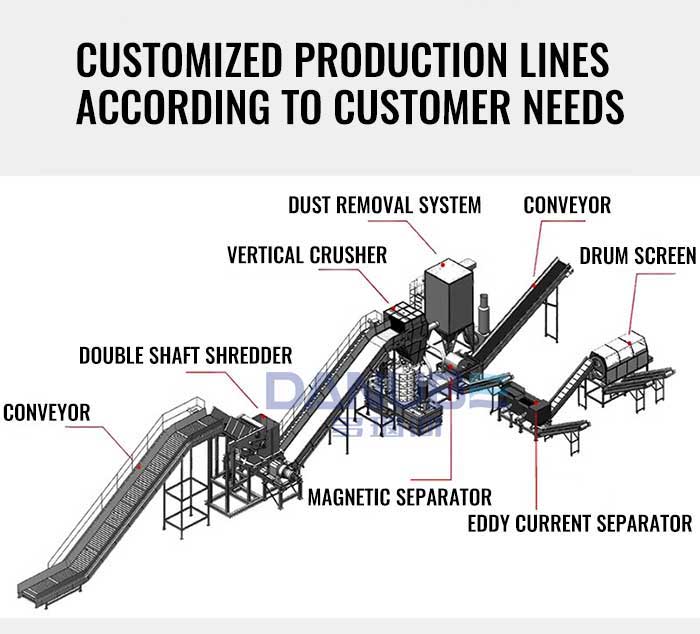

Plastic shredder machines are mainly used for shredding, recycling, and recycling of various waste household appliances shells, plastic barrels, oil barrels, and various plastic pipe materials on the market. The plastic barrel shredder can shred all kinds of plastic barrel materials at one time to obtain plastic blocks with smaller sizes. At the same time, the plastic barrel shredder is equipped with dust removal equipment and sorting and separation equipment, which can separate metal, plastic, and other materials. Impurities are effectively separated, which is convenient for users to classify and process waste materials and meet the conditions for plastic recycling.

The blades of the plastic bottle shredder recycling and processing production line equipment are made of high-strength alloy steel, which has the characteristics of strong wear resistance and high strength, and the differential speed between the shafts has the functions of tearing, squeezing, and biting. Professionally designed for shredding plastic barrels, it has the advantages of uniform discharge, large output, and low noise. The electrical part is programmed and controlled by Siemens electrical components, with functions such as automatic detection of overload protection.