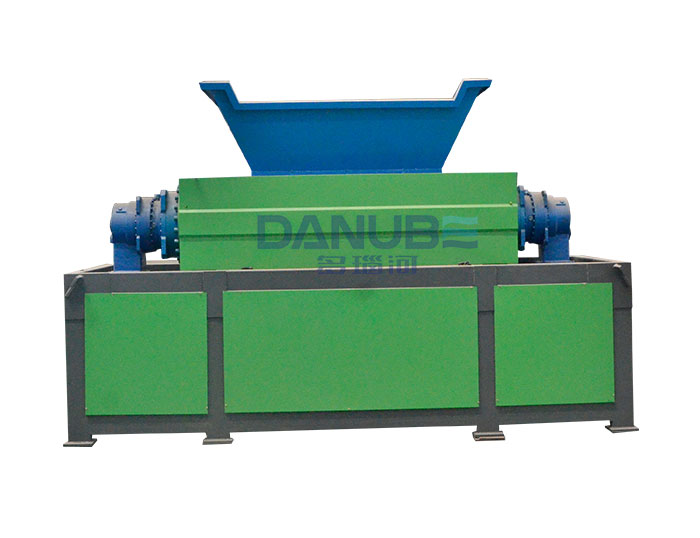

The steel shredder is a kind of steel recycling equipment handled by the scrap steel shredder. From the perspective of the scrap steel processing industry, the steel shredder is an important scrap recycling equipment in today’s society.

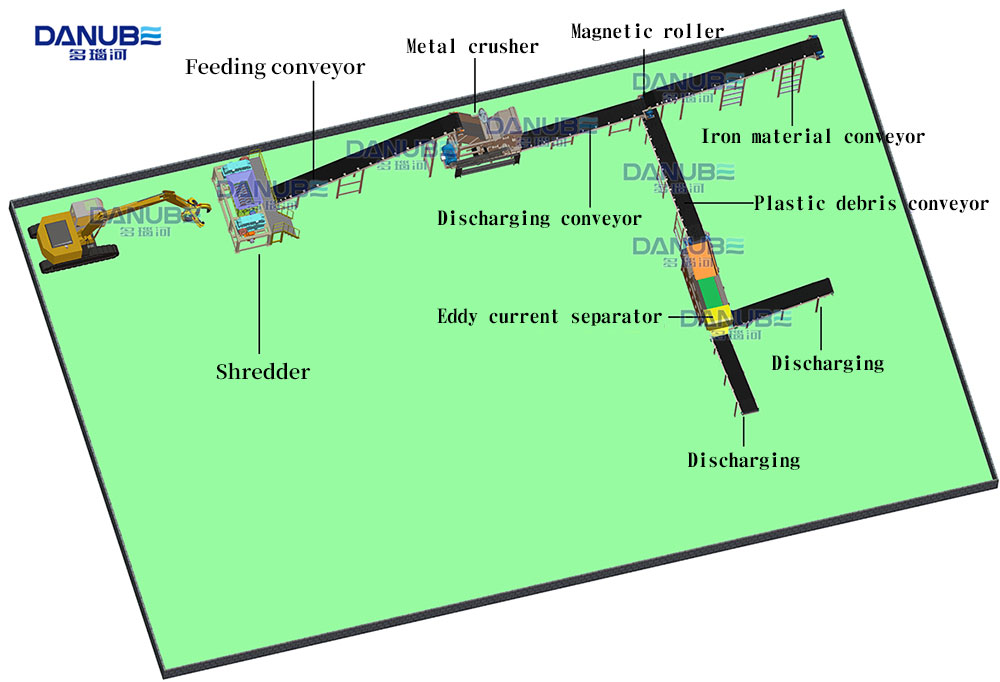

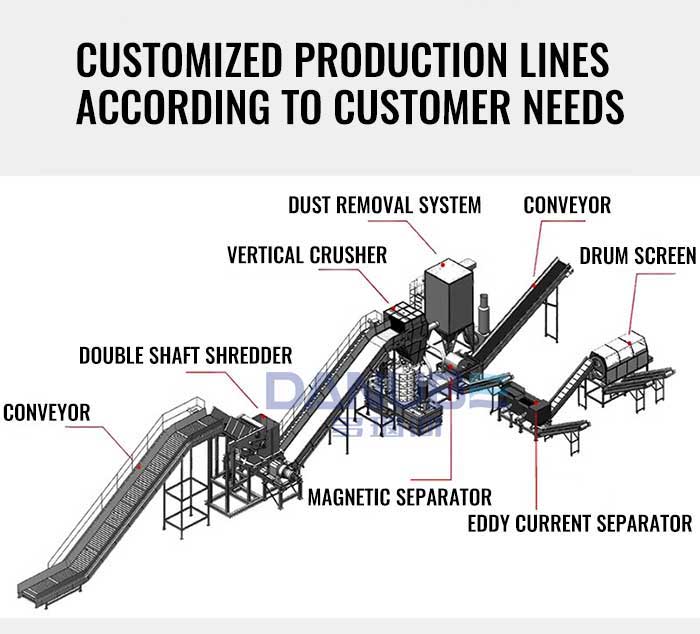

With the emphasis on environmental protection and the profit stimulation of resource recycling and processing, the entire scrap steel recycling market has shown a highly active state. At the same time, the investment demand for steel shredding equipment is also increasing. scrap steel shredder is a piece of key equipment for pre-shredding, middle-shredding, impurity removal, disassembly, and encryption molding of scrap steel products.

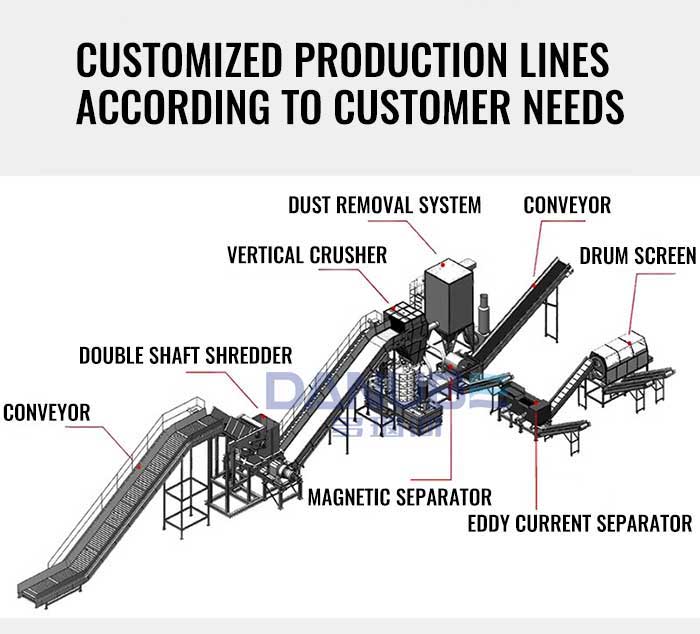

When the scrap steel shredder recycling processing production line equipment processes the materials, the materials will enter the shredding box through the feeding system, and the box is loaded with shredding blades, and the materials are torn, squeezed, and sheared by the shredding blades. The combined effect is shredded into small pieces and discharged from the lower part of the box.

steel Shredder Machine Features

1. steel shredder is a new generation of high-pressure, high-torque, high-shear, high-compression, and low-speed instant crushing technology products designed and developed by the self-designed and developed by comprehensive shredder technology.

2. The steel shredder product is equipped with a high-torque feed cutter head, which can easily penetrate, tear, hook and hook iron sheets, steel hoses, aluminum alloy castings, and other broken objects to automatically eat materials. Many difficult to solve raw materials are due to their large size.

3. The new generation of steel crushing technology, although the speed is low, its crushing time is short and the crushing frequency is high, not only the production capacity is much higher than the same model shredder, its energy consumption and wear are also very low.

4. The steel shredder uses the crushing principles of high-pressure shearing, heavy blow, shredding, etc., simply changing the shape of the cutter head can realize the multi-purpose crushing, separation, rust removal, impurity removal, compaction, and other effects of a machine.

5. The steel shredder realizes the characteristics of no splash, no pollution, no noise, no dust, more energy-saving, and safer by virtue of the low speed of 21-45 revolutions per minute. It is used in the recycling of scrap steel, waste plastic, and waste wood. The market is shining and popular.

steel Shredder Performance

☞ The housing of the steel shredder is made of high manganese steel, and the design reinforcement baffle is high manganese steel heat treatment. The high manganese alloy is used as the cutter head and liner, and the wearing parts are more durable.

☞ The fully enclosed working mode of the steel shredder increases the safety factor of the equipment and ensures safe production.

☞ Self-developed steel shredder, anti-seize device, 5 seconds reversal, to solve technical problems.

☞ steel shredders all use open and disassembled cutter heads, which are low cost and simple to maintain. The shape of the cutter head is easier and smoother to crush materials.

☞ The box body adopts reinforced ribs and two-guaranteed welding technology to ensure that the box body is more durable. The hydraulic device is used to open the box body, which is more convenient for unpacking and replacement.