【Video display – click to play】

Solid waste treatment equipment product introduction

Solid waste treatment equipment is a comprehensive treatment system designed to solve urban and industrial solid waste. The solid waste management equipment effectively reduces the volume of garbage, separates recyclable materials, and finally achieves the reduction, resource utilization and harmless treatment of solid waste through various treatment methods such as crushing, sorting, resource utilization and harmlessness.

Features of Solid waste treatment equipment

Wide treatment range Applicable to various solid waste types such as domestic garbage, industrial garbage, construction waste, hazardous waste, etc.

Efficient resource utilization Separates and recycles recyclables (such as metals, plastics, paper, etc.), and converts organic matter into energy or compost raw materials.

Modular design Each module of the equipment operates independently and can be flexibly configured according to different needs, such as crusher, screening equipment, magnetic separator, air separator, etc.

Intelligent control is equipped with PLC automatic control system, which monitors and adjusts the operation status of the equipment in real time, and is convenient, safe and reliable to operate.

Environmentally friendly and efficient Equipped with dust collection, wastewater treatment and gas purification systems, it meets environmental protection standards and reduces secondary pollution.

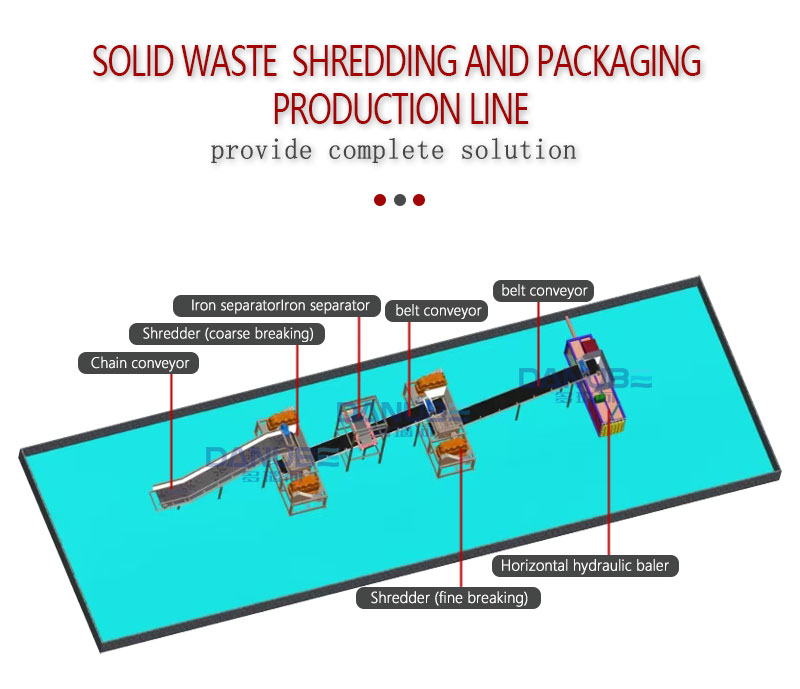

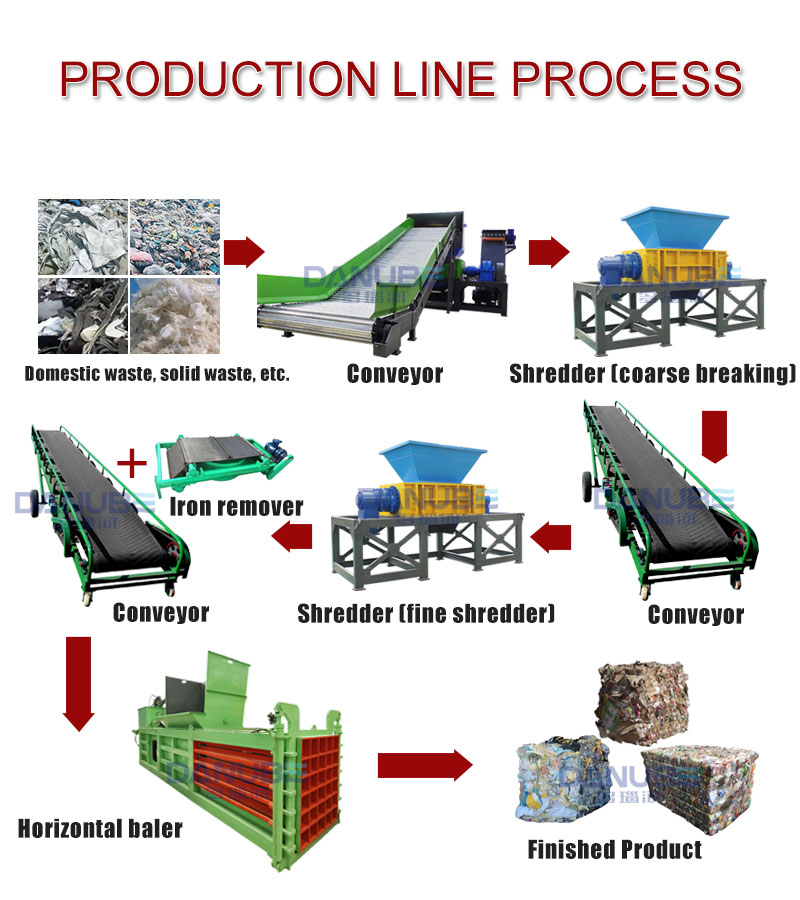

Working principle of Solid waste treatment equipment

In the pre-treatment stage, solid waste enters the crusher through a conveyor belt. After coarse and fine crushing, the large volume of waste is reduced to easy-to-handle particles.

Sorting stage

Magnetic separation: Use a magnetic separator to separate ferromagnetic metals.

Eddy current separation: Used to separate non-ferrous metals such as aluminum and copper.

Wind separation: Separate light materials (such as plastics and paper) from heavy materials (such as glass and stones) according to the density difference of the materials.

Screening: Use a drum screen or a vibrating screen to classify the particle size of the materials.

Resource utilization stage

Recyclable metals, plastics, etc. are recycled and reused through sorting equipment.

Organic matter is converted into biogas, compost or biochar through anaerobic fermentation or pyrolysis.

Non-recyclable inert materials can be used in building materials production or safe landfill.

Harmless treatment stage

Hazardous waste is treated by high-temperature incineration or solidification stabilization to reduce environmental hazards.

The matching flue gas purification equipment can effectively remove harmful gases (such as dioxins and acid gases).

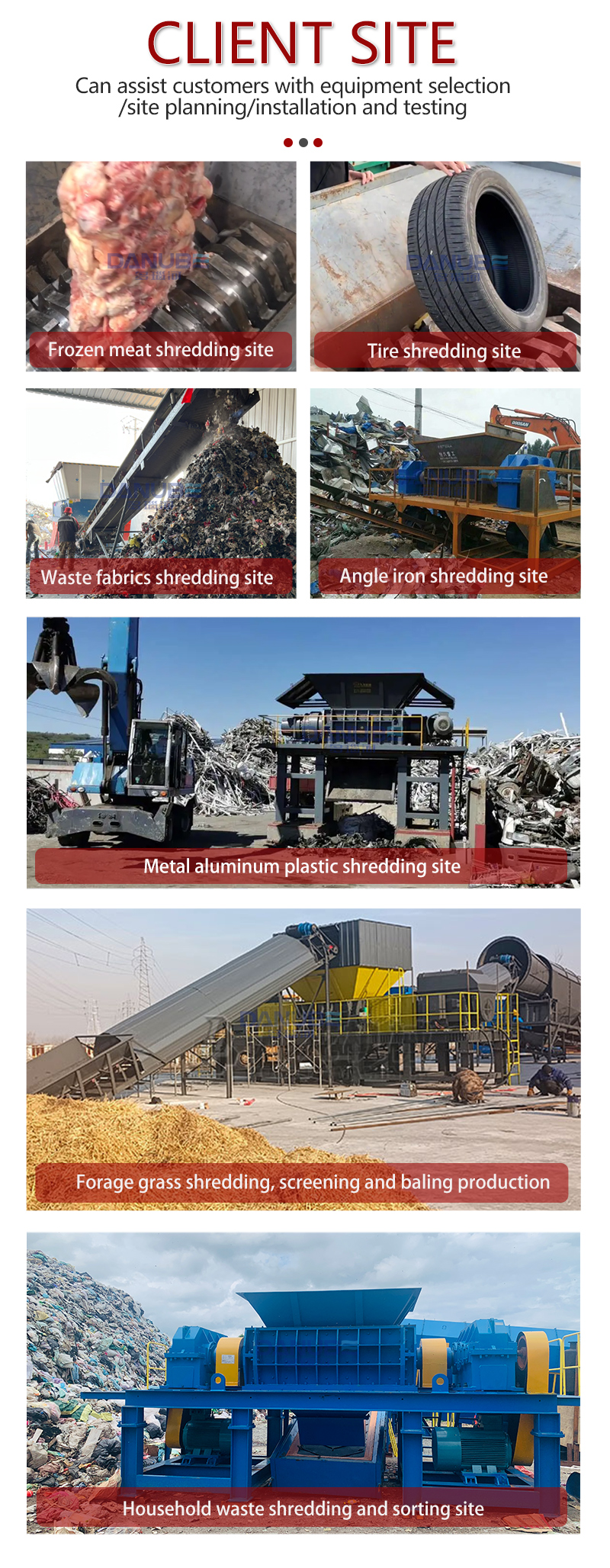

Application scenarios of Solid waste treatment equipment

Urban domestic waste treatment provides comprehensive solutions for treating household garbage, garden waste, etc.

Industrial park solid waste treatment targets waste generated by industrial production and recycles and harmlessly treats it.

Construction waste treatment recycles concrete, bricks, steel bars, etc. generated by building demolition.

Hazardous waste treatment includes solid waste that requires special treatment, such as medical waste and chemical waste.