【Video display – click to play】

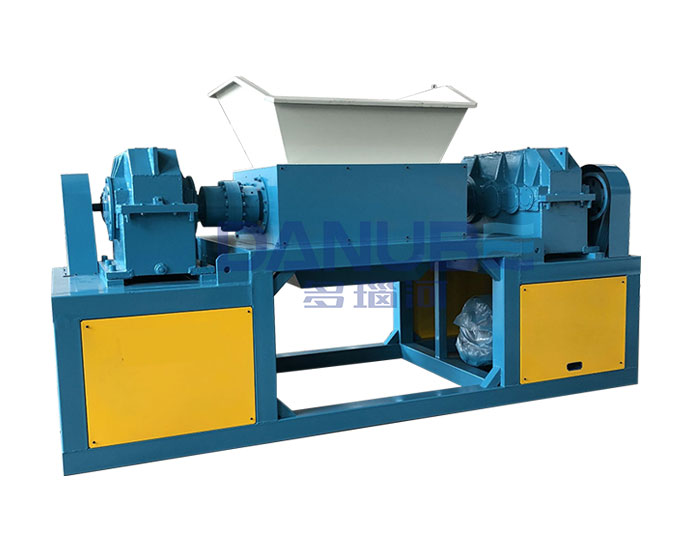

Product Introduction:

The common structures of textile shredder are single-axis, double-axis, and four-axis. The shredder is driven by a planetary gear reducer. The blades are made of high-strength alloy steel, which has strong wear resistance and high strength. The shafts rotate at differential speeds, and have functions such as tearing, squeezing, and biting. It is designed for various household waste materials and is suitable for crushing various household waste, such as: used clothes, used shoes, used quilts, used daily necessities, packaging bags, used wood, used plastics, food waste, medical waste, etc. Design is provided according to customer requirements. It has the advantages of uniform discharge, controllable size, large output, and low noise.

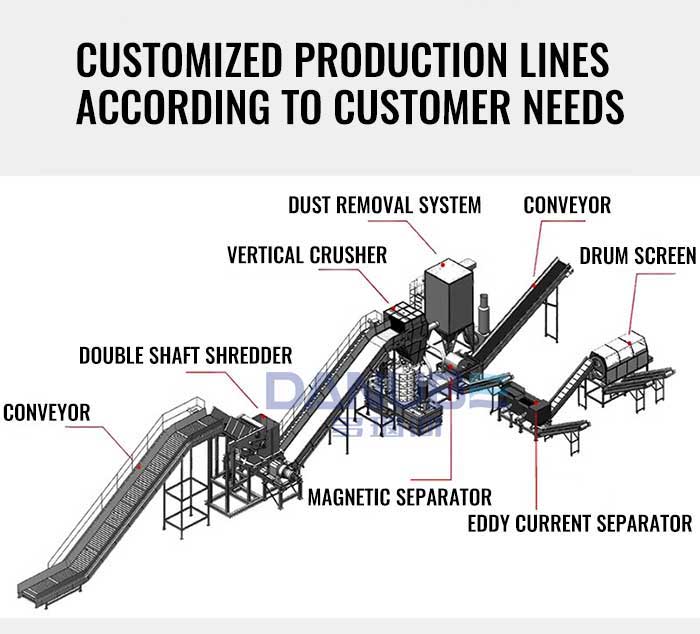

Product advantages of textile shredder machine:

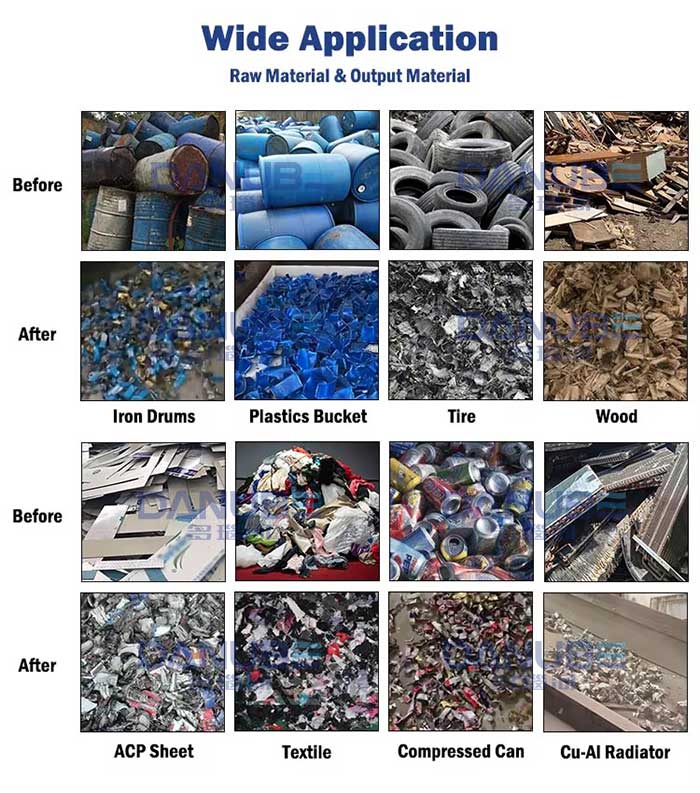

1. This machine is suitable for processing oversized fabrics, mattresses, clothes, sheets, curtains, quilts and other textiles.

2. The machine has a large feed port and can freely place large plastic products.

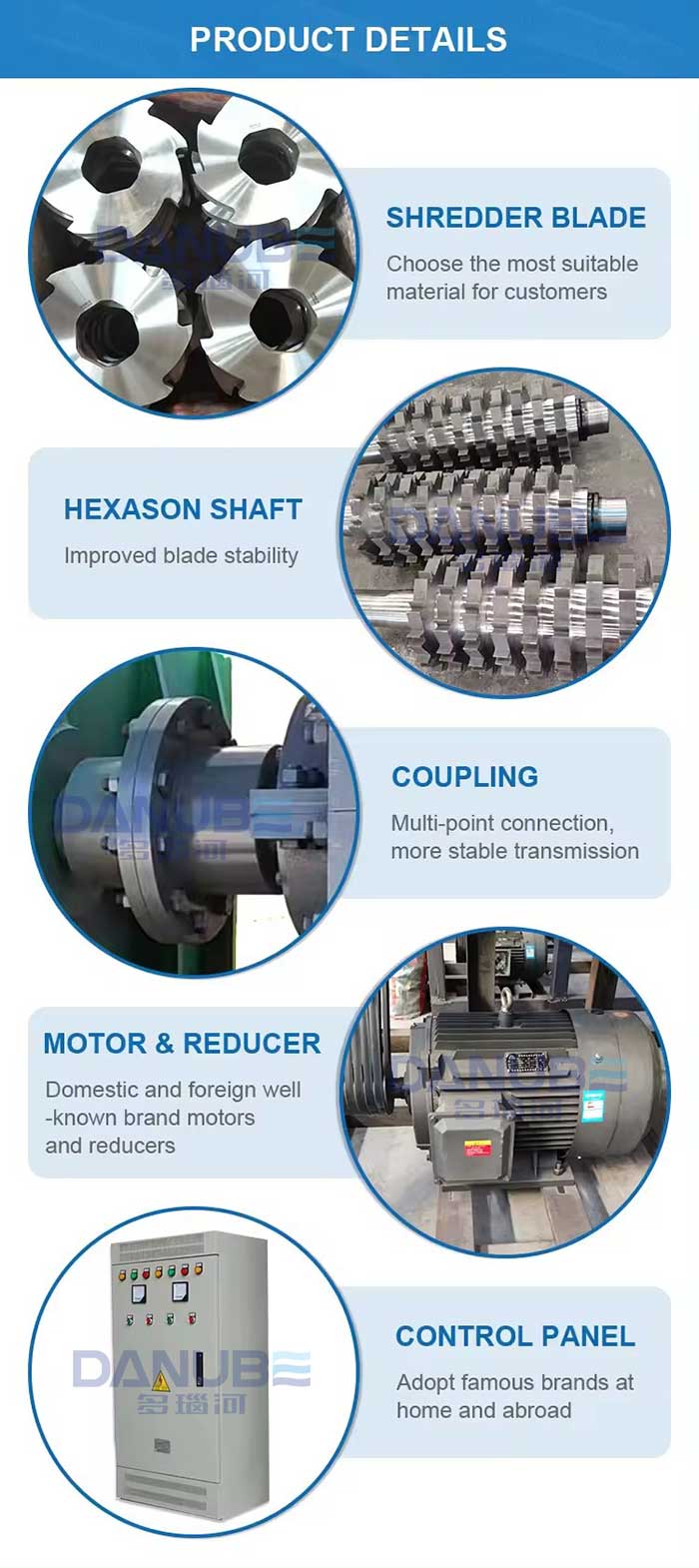

3. The rotating blade, cutting blade and blade are specially designed with high efficiency and high output.

4. This machine is controlled by PLC system, the blade can rotate in reverse, and it can be automatically closed in case of accidents, which is highly safe.

5. The machine runs slowly, with low noise and less dust.

6. The auxiliary blade is refined by forging and milling process, and the main blade is made of special alloy steel with high strength and strong wear resistance.

According to the different products we use, we have different blades to choose from. The textile shredding machine is made of two-axis blades cutting each other to meet the requirements of shredding materials. The size of the shredded material depends on the thickness and number of teeth of the shredding blade. The thinner the blade, the smaller the size of the shredded material. The greater the number of teeth, the shorter the length of the shredded material. The thicker the blade, the harder the material it can tear.

Mongolia Customer Case

Chile Customer Case