Vegetable drying machine introduction

Working principle of vegetable drying machine

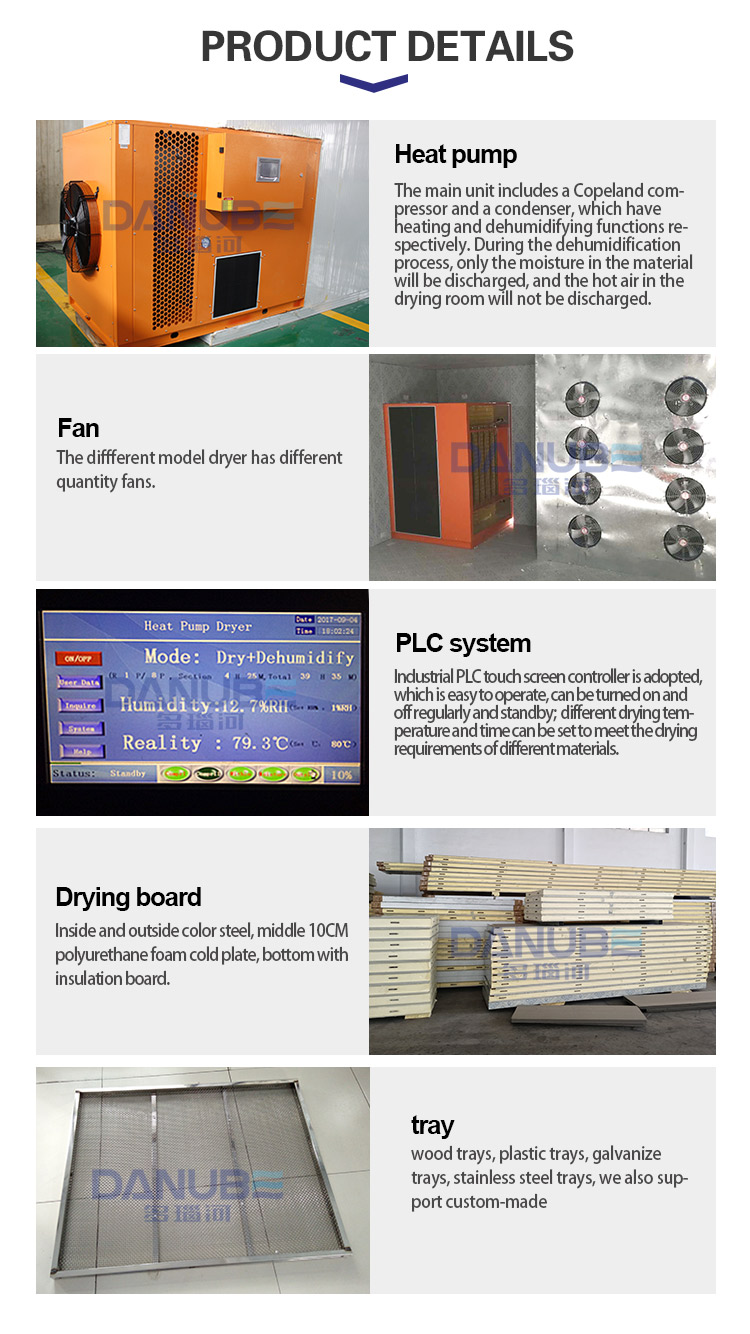

The vegetable heat pump dryer adopts the principle of reverse Carnot cycle. It absorbs low-temperature heat energy in the air and becomes high-temperature heat energy after efficient heat collection and integration of the heat pump system, which is transported to the drying room to circulate heating and drying the vegetable, and the hot and humid air in the drying room is directly discharged to the outside of the drying room through the dehumidifier.

The vegetable heat pump dryer can quickly remove the water in the vegetable without affecting the original color, shape, and nutrient content of the vegetable. The vegetable drying oven is equipped with a computer control system, which can realize automatic temperature control. The drying temperature range of the heat pump dryer is 20-80°C, and the materials suitable for drying are very wide, such as grains, edible fungi, medicines, seafood, bacon, vegetables and vegetables, tobacco leaves, seeds, spices, etc.

【Video display – click to play】

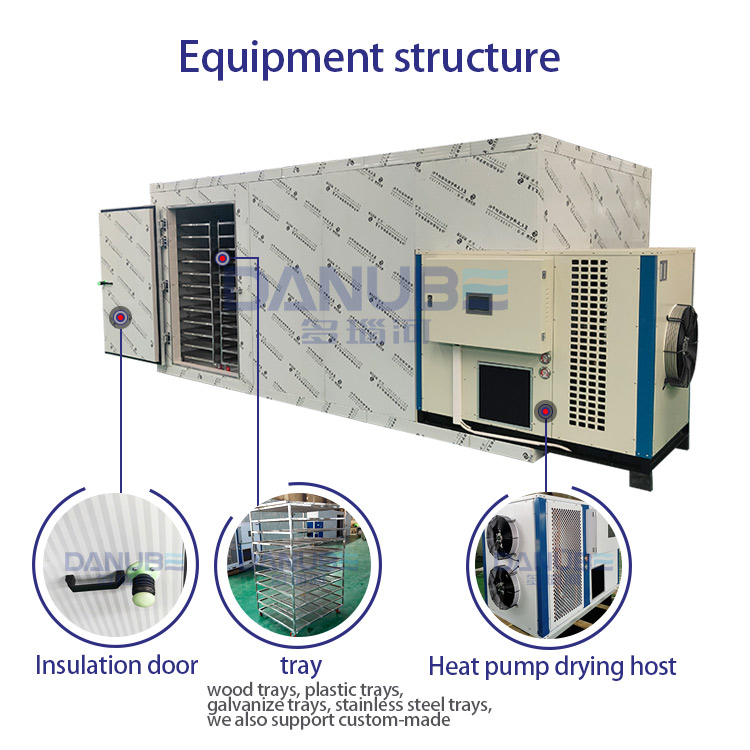

Components of vegetable drying machine

One set vegetable drying machine contains:

1:Heat pump drying host

2:Drying chamber

3:Fan frame with fan

4:Trolley with tray

The drying chamber is used 100mm polyurethane insulation board, supporting 304 stainless steel trolleys and trays.

Advantages of vegetable drying machine

1:High quality: vegetable can be maintained full of shape, bright, color.

2:Fast dehydration: 4-6 hours per batch according to different materials.

3:Wide application: a variety of materials can be dried like vegetables, vegetables, herbs, meat, seafood and etc.

4:Efficient and environmentally friendly, absorb heat from the air to dry the materials, without any pollution emissions and save about 70% of operating costs compared with traditional drying technology.

5:Simple operation, easy installation or no installation.

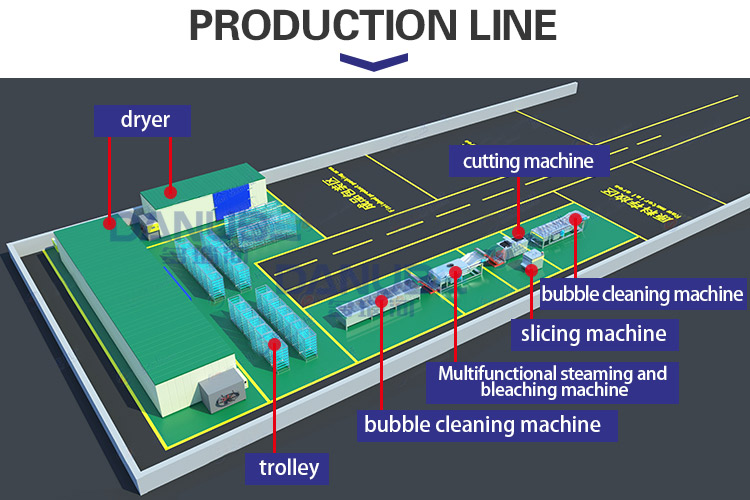

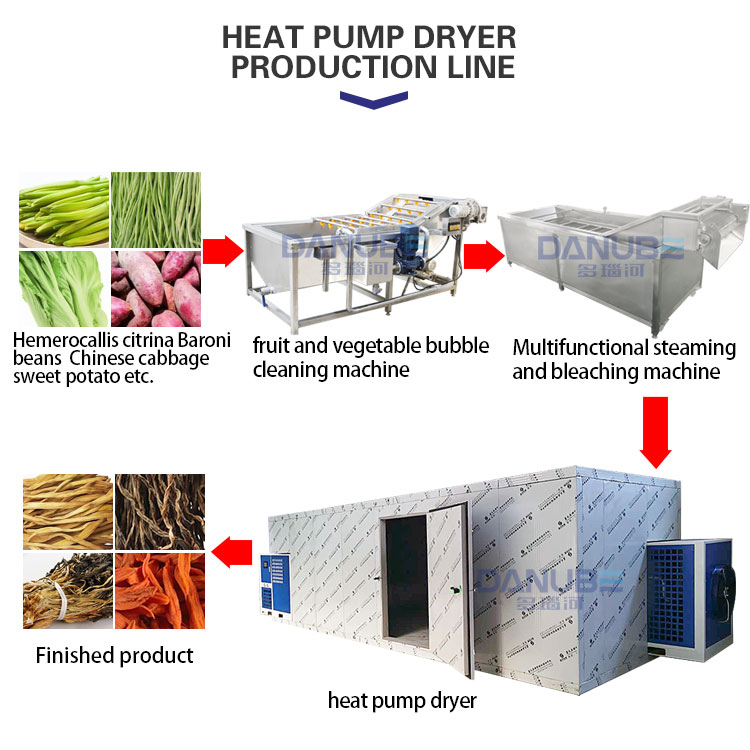

vegetable drying process

How to dry vegetable

1: pick vegetable

Due to the different quality and maturity of vegetable, unsuitable vegetable should be selected before drying.

2: clean the vegetable

To clean the surface dust of vegetable, if the output is large, it is recommended to use a professional vegetable cleaning machine.

3: vegetable slice

vegetables need to be sliced.

4: Put the vegetable on the tray

Spread the vegetable evenly on the tray with a thickness of about 5 cm, and then put them in the drying oven.

5: vegetable drying

Set the temperature in the drying room to 65°C and the humidity to 10%. Dry for 6~8 hours to complete the vegetable drying.

6: storage

The dried vegetable will regain moisture when they are in direct contact with the air, so a sealed package is required. If you use vacuum packaging, you can better preserve the color and aroma of vegetable.

Technical parameters of vegetable drying machine

| Drying oven list | ||||||||||

| type | machine size(MM) | Capacity (KG) | power | Qty of fan | fan power | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 3P A | 3500×2200×2200 | 200-400 | 2.25 | 6 | 0.25/pc | 3.75 | 6 | 78 | 670×810 | 600×800 |

| 8P A | 5300×2200×2800 | 450-750 | 6 | 12 | 0.37/pc | 10.44 | 6 | 156 | 1210×870 | 600×800 |

| 15P | 7500×3000×2800 | 900-1500 | 11.25 | 12 | 0.55/pc | 17.85 | 12 | 312 | 1210×870 | 600×800 |

| 1P D | 1180×680×1800 | 50-80 | 1 | — | — | 1 | — | 15 | — | 600×800 |

| 3P D | 2100×930×2100 | 120-300 | 3.5 | — | — | 3.5 | — | 40/60 | — | 600×800 |

| 8P D | 4000×1960×2050 | 650-1000 | 8 | — | — | 8 | 8 | 232 | 600×800 | 600×800 |

| The drying machine can be equipped according to the user’s requirements and the production demands. | ||||||||||