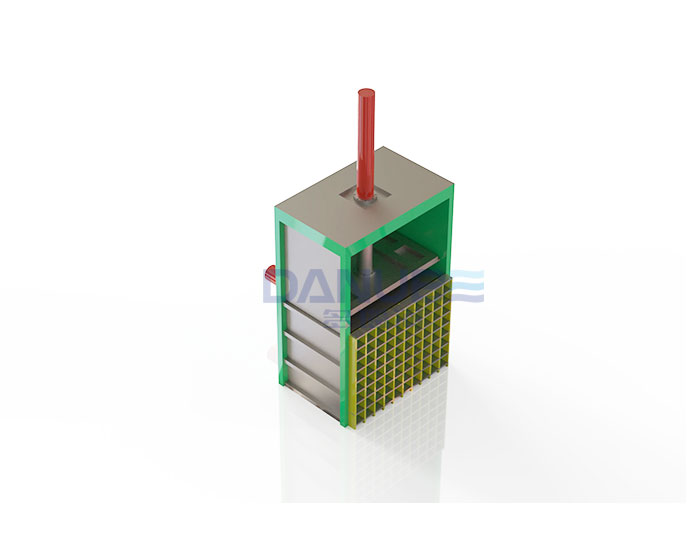

The vertical waste baler is to reinforce the packaged goods so that the goods will not be scattered due to inadequate tying during transportation and storage, and the tying will be neat and beautiful. At the same time, it is ideal equipment for improving work efficiency, reducing labor intensity, saving manpower, and reducing transportation costs. Reduce waste storage space and save up to 80% of stacking space, which is conducive to environmental protection and waste recycling.

Typical recyclable commodities often baled include plastic packaging, plastic bottles, paper products, cardboard packaging, light gauge ferrous and non-ferrous metals, and shrink wrap. While all vertical balers work in a similar way to each other, various models with different sizes are available to suit varying requirements.

Vertical Balers are available in sizes that produce bales of up to 5T, 10T, 20T. Additionally, optional larger and 3-phases units are available upon request.

1. Significant waste volume reduction

2. Unique compact design for precious floor space-saving

3. Energy-efficient

4. Reduces recycling costs

5. Reduce cost in labor, time, storage,and transportation

☆ Improve your waste and sorting processes with our Vertical Balers!

Vertical Balers can compact virtually any product into a bale. Our range of balers has been built with safety in mind. With many ergonomic and efficiency benefits, they can be introduced effectively in any workplace.

▶ There are different ways of turning the bag, pushing the bag (side pushing and pushing), or manually carrying the bag (packing).

▶ Compression chamber size and packaging size can be customized according to customer requirements.

▶ The pushing cylinder and the push head are connected by a spherical structure, which has good reliability and long service life for the oil seal.

▶ The feeding port provides a dispersive shearing knife with high shearing efficiency.

▶ Low noise hydraulic circuit design, high efficiency, and low failure.

▶ Easy to install, unfounded.

▶ Button operation, PLC control, safe and reliable.

We have horizontal balers and vertical balers, if you are not sure which product will work the best for you, contact our knowledgeable sales team for more information and quotation today!

|

Model

|

Pressure

|

Power(kw)

|

Machine Inner Dimension

|

Bale Size(L*W*H,H is adjustable)

|

Capacity

|

Machine Weight

|

|

(t)

|

(kw)

|

(mm)

|

(mm)

|

(t)

|

(t)

|

|

|

15

|

15T

|

5.5

|

850*600*1300

|

890*610*500-1100

|

1-1.5

|

1.5

|

|

30

|

30T

|

7.5

|

890*610*1300

|

890*610*500-1100

|

1.5-2

|

1.8

|

|

60

|

60T

|

11

|

900*600*1300

|

890*610*500-1100

|

2-2.5

|

3.5

|

|

80

|

80T

|

15

|

1100*800*1500

|

1200*800*500-1100

|

3-3.5

|

4.5

|

|

100

|

100T

|

18.5

|

1100*800*1500

|

1200*800*500-1100

|

3.5-4

|

5.5

|