Wood drying machine introduction

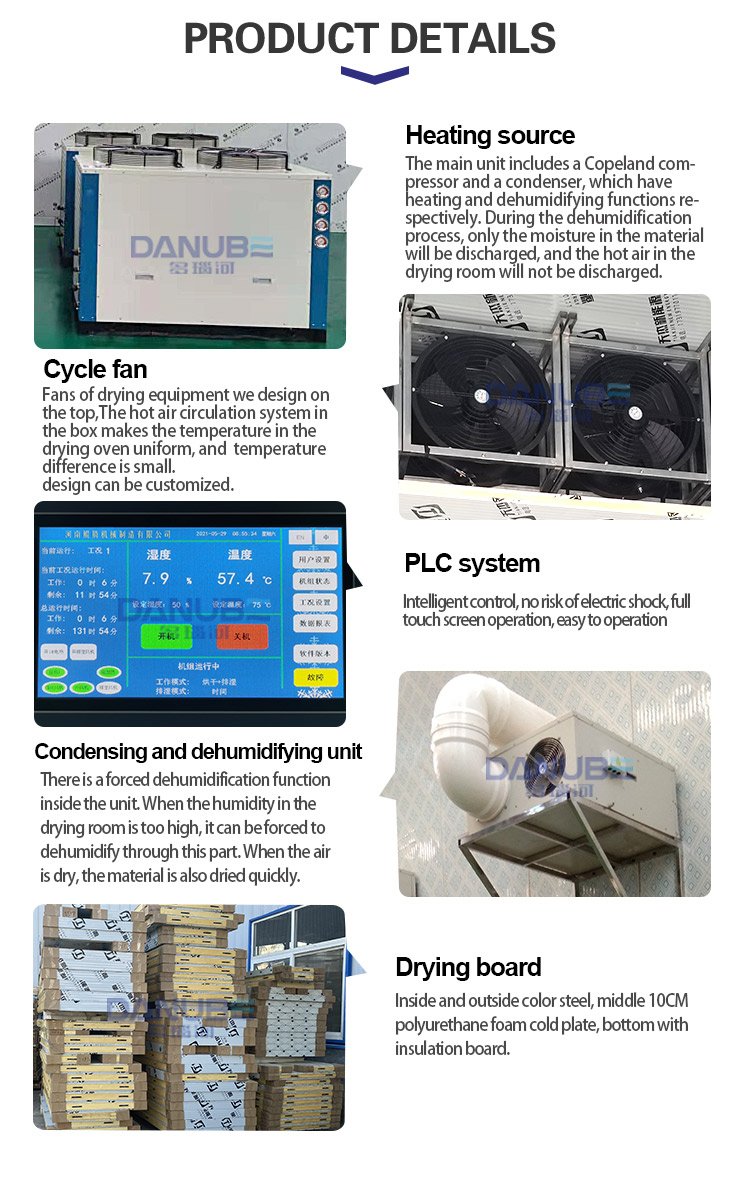

The wood drying machine adopts a closed-loop drying method to dry various tree species and wood pieces, and make automatic drying,low operating costs, automatic PLC control for drying, short drying time, No cracking, no deformation, no discoloration, high working efficiency, no pollution in the drying process.

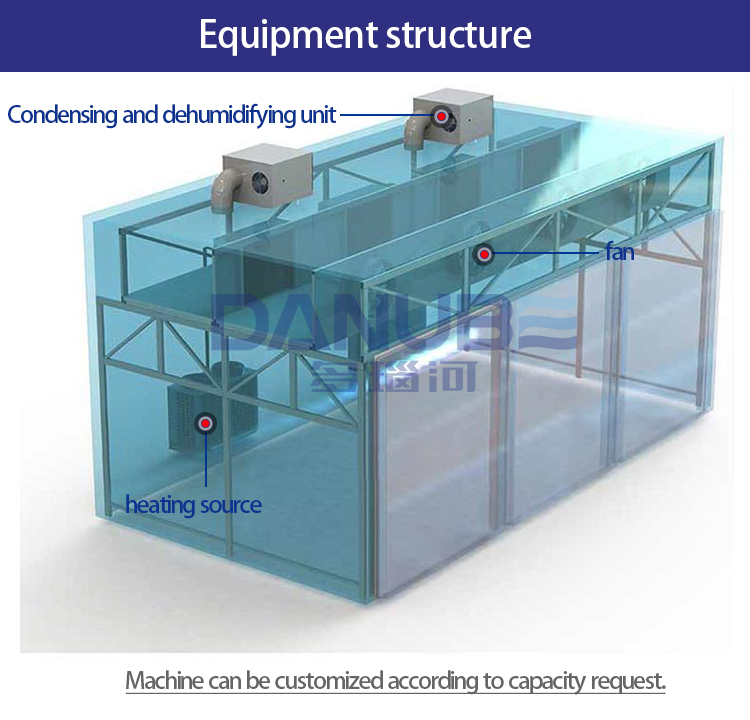

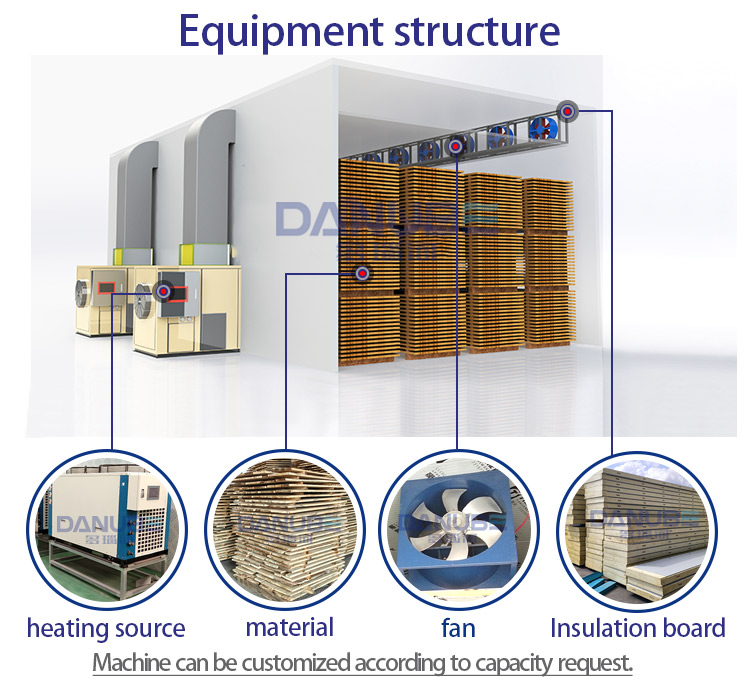

Working principle

Uniform air volume, high wind speed, evenly temperature throughout the wood dryer.High temperature and humidity resistant fan used in drying room, so as to improve the working efficiency of the drying room, on the other hand it can avoid some bad situation, like wood mildew, or crack.

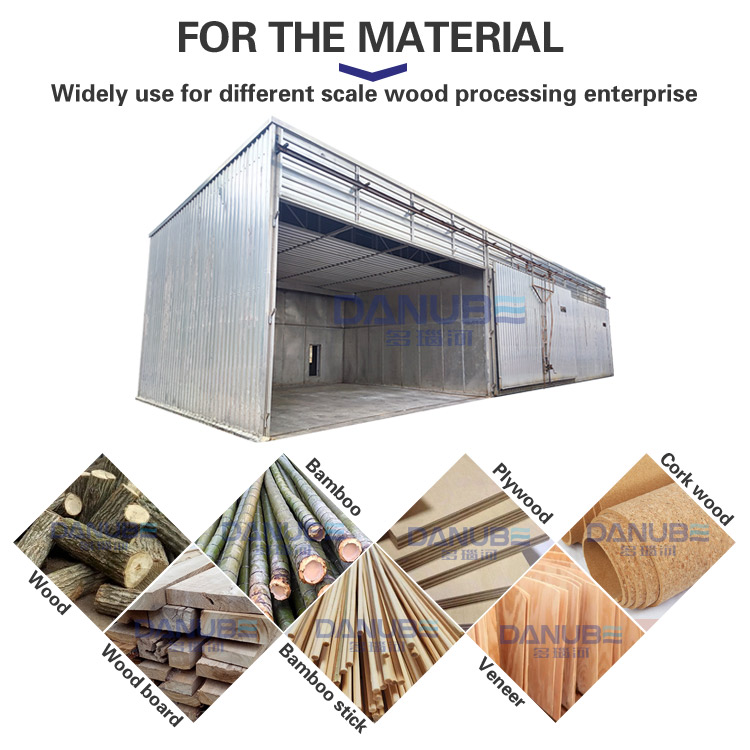

Applicable material

Fir, poplar, elm, pine, cypress, eucalyptus, apricot, pear, oak, mahogany, nanmu, paulownia, bamboo and other tree species, various specifications, various uses of wood can be dried.

Product characteristics

● Low noise and low consumption

● Dry evenly

● High efficiency and energy saving

● Safe and reliable

● Strong hardness and durable

● Short drying cycle

● Low drying cost

● Good drying quality

● Long service life and customizable equipment

Equipment on-site installation, simple operation, simple control, good temperature control, the wood after drying is not deformed or cracked, the company was founded more than 20 years, by professional technical research and development team, engaged in drying industry for more than 20 years, welcome to consult.